|

Product Features

-

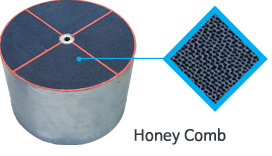

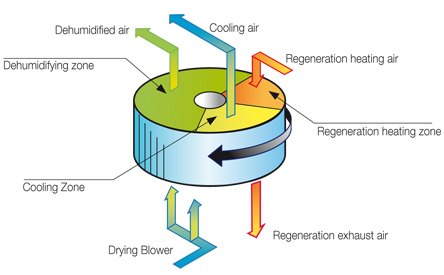

Honeycomb Rotor Type

Endurable & Semipermanent rotor which adopt honeycomb structure molded in molecular sieve

-

Guaranties dew point

Stable over dew point -40°C

-

Simple structure & Elegant Look

Simple structure makes easier equipment manintenance

-

Touch Type Implementation System is convenient

to use equipment

PLC & Graphic Touch Panel Stereogram Reserve Function For Dried Material Feeding Process, Alarm function, Embedded cleaning valve

-

Fool/proof Response model

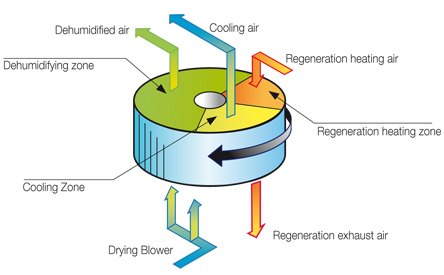

Flow Diagram

Flow Diagram

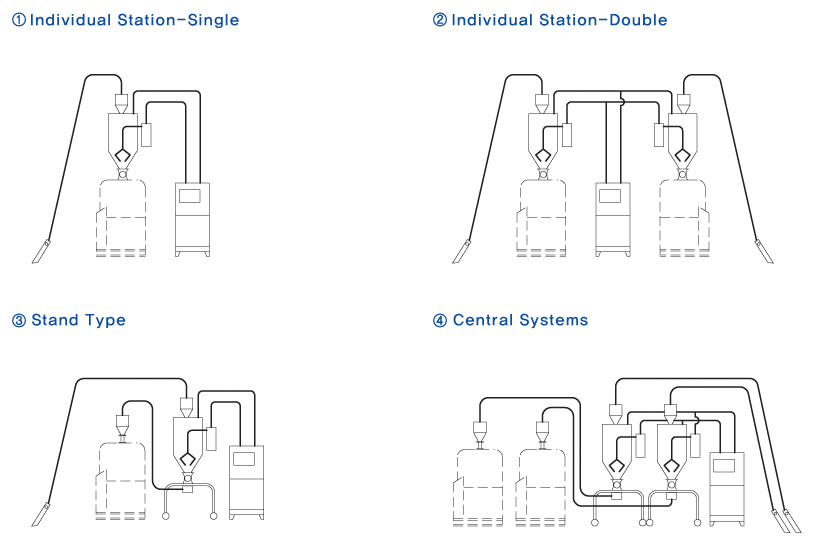

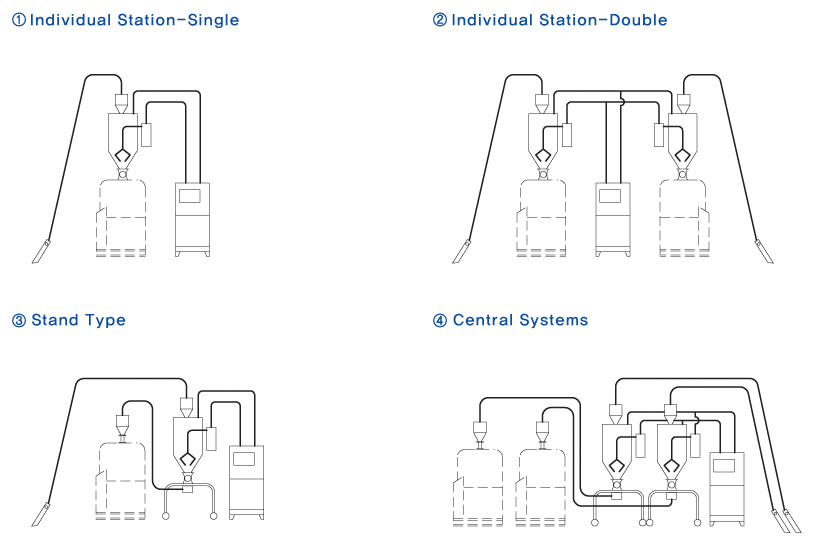

Installation Style

Drying Conditions Illustrates

| |

|

| Condition A Summer |

With hopper dryer in 80% relative humidity and 20℃ surrounding temperature |

| Condition B Spring |

With hopper dryer in 70% relative humidity and 12℃ surrounding temperature |

| Condition C No relation |

With dehumidifer, average operating Dew Point -40℃, not caring surrounding temperature |

Specifications

|

Model

Spec |

UNIT |

HKAD-202 |

HKAD-205 |

HKAD-208 |

HKAD-210 |

HKAD-220 |

| Air flow |

m3/hr |

50/60Hz |

170/200 |

260/300 |

340/400 |

430/500 |

850/1000 |

| Drying Temperature |

Max, ℃ |

MT Type |

150 |

150 |

150 |

150 |

150 |

| HT Type |

180 |

180 |

180 |

180 |

180 |

| Honey Comb Model |

HC- |

- |

3520 |

4530 |

4530 |

6030 |

6030 |

| Rotation Motor |

W |

- |

25 |

25 |

25 |

25 |

25W-2 |

| PIPE DIA DRYING/RENEWING/COOLING |

mm |

- |

76/51/38 |

89/61/51 |

89/61/51 |

114/76/51 |

152/76/51 |

| Drying Blower |

kW |

- |

1.9 |

2.6 |

6.3 |

6.3 |

12.6 |

| Regeneration Blower |

kW |

- |

0.2 |

0.5 |

0.5 |

0.8 |

2.6 |

| Drying Heater |

kW |

MT Type |

9 |

18 |

18 |

24 |

40 |

| HT Type |

12 |

24 |

24 |

30 |

48 |

| Regeneration Heater |

kW |

- |

6 |

9 |

9 |

12 |

24 |

| Air Cooler |

ℓ/min |

Kcal/hr |

40/4,000 |

80/8,000 |

80/8,000 |

120/12,000 |

240/24,000 |

| IN/OUT Size |

A |

mm |

20A x ∅16 |

25A x ∅19 |

25A x ∅19 |

25A x ∅25 |

32A x ∅32 |

| Dimensions |

mm |

Width |

700 |

800 |

800 |

900 |

1250 |

| Length |

840 |

1000 |

1000 |

1200 |

1600 |

| Height |

1550 |

1800 |

1800 |

1900 |

2300 |

| Application Hopper |

Kg/b |

- |

200~300K |

400~600K |

800K |

1000~1500K |

2000~3000K |

| · DEW POINT & EQUIPMENT CAPACITY DIFER DEPEND IN THE EXTERNAL CONDITIONS (27 °C & RH 70%) |

Drying Performance

| Material |

Temp' (℃) |

Initial (%) |

Final (%) |

*K=m3/hr |

Time (hr) |

Drying capacity in kg/hr |

| HKCD-101 |

HKAD-201 |

HKAD-202 |

HKAD-205 |

HKAD-208 |

HKAD-210 |

HKAD-220 |

| ABS |

80 |

0.3 |

0.02 |

1.5 |

2~3 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| CA |

60~70 |

1 |

0.02 |

2.1 |

2~3 |

47 |

47 |

81 |

119 |

143 |

190 |

380 |

| PA6,66 |

75~80 |

1 |

0.04 |

2 |

4~6 |

50 |

50 |

85 |

125 |

150 |

200 |

400 |

| PBT |

120~140 |

0.2 |

0.02 |

2 |

3~4 |

50 |

50 |

85 |

125 |

150 |

200 |

400 |

| PC |

120 |

0.3 |

0.01 |

1.5 |

2~3 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| PET |

140~160 |

0.2 |

0.005 |

3 |

4~6 |

33 |

33 |

57 |

83 |

100 |

133 |

266 |

| PETG |

60~70 |

0.2 |

0.02 |

3.7 |

3~4 |

27 |

27 |

46 |

67 |

81 |

108 |

216 |

| PMMA |

80 |

0.2 |

0.02 |

1.5 |

3~4 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| POM |

100 |

0.2 |

0.02 |

1.5 |

2~3 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| PPO |

110~120 |

0.1 |

0.04 |

1.5 |

1~2 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| PPS |

140~160 |

0.1 |

0.02 |

1.5 |

3~4 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

| SAN |

140~160 |

0.1 |

0.05 |

1.5 |

2~3 |

67 |

67 |

113 |

167 |

200 |

267 |

534 |

· K=m3/hr for a production of 1kg/h - Above drying performance can change subject to the grades of material, the material’s initial moisture content and the drying temperature.

· Option:Dew point meter |

|

|

.png)

.jpg)