|

Product Features

To maintain optimum dehumidifying condition, this dryer apply the core technology 'MYCOM process control system'. Through innovative heater and precision air-control equipment, prevent over-dry of raw material and maintain optimum dehumidifying-ability.

-

Compressed-air type (HKZD Series)

It is a system using compressor-air to dry Hycroscope, Polymer. The series are made up of 3 models, The capacity is from min.2kg/hr to max.18kg/hr. The average dew-point of ZETA dryer gurantee -20℃. ZETA dryer is designed to be suitable for Injection Mold Machine and Blow Molding Machine. In special, when use a little quantity of raw material, Be available to be used with optimal condition.

-

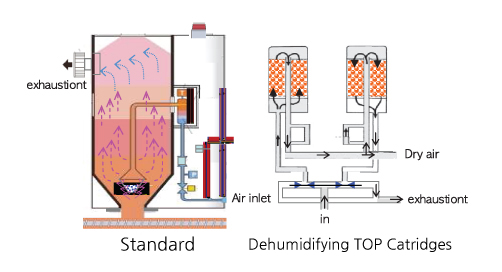

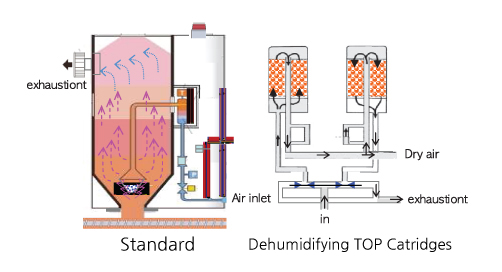

Dehumidifying TOP Cartridge type (HKZD-G Series)

When require more low dew-point(-40℃) than using compress air type, additionally apply Dehumidifying TOP Cartridge type. Due to material's nature, it is used when require low dew-point -40℃

-

Touch Screen Panel / Dry scheduling

-

FOOL/PROOF Response model

Operating Principles

Material Loading Method

Specifications

| Type |

Standard |

HKZAD-12 |

HKZAD-25 |

HKZAD-50 |

| Dehumidifying TOP |

HKZAD-12G |

HKZAD-25G |

HKZAD-50G |

| DEW Point |

standard |

-20℃ |

| Dehumidifying TOP |

-40℃ |

| Hopper Volume(kg/b) |

12 |

25 |

50 |

| Compressed Air (㎥/hr) |

5-8 |

6-20 |

9-34 |

| Drying Capacity(kg/hr) |

2-3.5 |

6-10 |

9-18 |

| Heating Power(kW) |

1 |

2 |

2.6 |

| Dimension(∅x h) |

290 x 760 |

358 x 930 |

444 x 1080 |

| Voltage |

220V x 1∅ 50/60Hz |

| Temperature range |

40℃ ~ 160℃ |

| · Supply Compressor Air : Pressure dew point 5℃, Pressure 6~8kg/cm2 standard |

Drying Performance

| Model |

Material |

B. D |

Starting Moisture |

End Moisture |

Drying |

Drying capacity in kg/hr |

| Time |

Temp. |

HKZAD-12 |

HKZAD-25 |

HKZAD-50 |

| kg/cm³ |

% |

% |

h |

℃ |

kg/h |

kg/h |

kg/h |

| A |

ABS |

0.60 |

0.30 |

0.02 |

2.5~3 |

80 |

4.0 |

9.4 |

17.5 |

| CA |

0.50 |

1.00 |

0.02 |

2.5~3 |

75 |

2.8 |

6.5 |

12.2 |

| PA6,66 |

0.65 |

1.00 |

0.04 |

4~6 |

80 |

2.8 |

5.6 |

9.8 |

| PBT |

0.70 |

0.30 |

0.02 |

4 |

125 |

3.4 |

7.8 |

14.6 |

| PC |

0.70 |

0.30 |

0.01 |

2.5~3 |

120 |

4.0 |

9.1 |

17.0 |

| PE |

0.60 |

0.10 |

0.01 |

2.5 |

90 |

4.1 |

9.4 |

17.5 |

| PES |

0.70 |

0.80 |

0.02 |

4 |

150 |

3.0 |

7.0 |

12.8 |

| PMMA |

0.65 |

0.50 |

0.02 |

3 |

80 |

3.7 |

8.5 |

15.8 |

| POM |

0.60 |

0.20 |

0.02 |

3 |

100 |

3.4 |

7.8 |

14.6 |

| PPO |

0.50 |

0.13 |

0.04 |

2 |

120 |

4.3 |

9.8 |

18.3 |

| PPS |

0.60 |

0.10 |

0.02 |

3~4 |

140 |

2.9 |

6.7 |

12.5 |

| PC+ABS |

0.70 |

0.30 |

0.02 |

3 |

90 |

4.0 |

9.1 |

17.0 |

| SAN |

0.50 |

0.10 |

0.04 |

2~3 |

80 |

3.4 |

7.8 |

14.6 |

| TPE |

0.55 |

0.10 |

0.04 |

2~3 |

90 |

3.1 |

7.2 |

13.4 |

| B |

CP |

0.60 |

1.00 |

0.02 |

2.5~3 |

75 |

3.4 |

7.6 |

14.6 |

| PET(INJ) |

0.80 |

0.20 |

0.02 |

3~4 |

140 |

3.0 |

7.8 |

14.6 |

| PET(Perform) |

0.80 |

0.20 |

0.005 |

5~6 |

160 |

2.3 |

5.2 |

9.7 |

| PETG |

0.60 |

0.50 |

0.02 |

4~6 |

70 |

2.0 |

4.7 |

8.8 |

| PUR |

0.70 |

0.20 |

0.04 |

3 |

90 |

4.0 |

9.1 |

17.0 |

| PVC |

0.55 |

0.10 |

0.02 |

2 |

75 |

4.7 |

10.8 |

20.1 |

| PP+Talco |

0.60 |

0.10 |

0.02 |

2~3 |

90 |

4.1 |

9.4 |

17.5 |

| EVA |

0.60 |

0.10 |

0.01 |

4 |

40 |

2.6 |

6.0 |

11.0 |

| · May vary by the type of material and drying temperature, air compressor, depending on the condition of supply. |

|

|

.png)

.jpg)

.png)